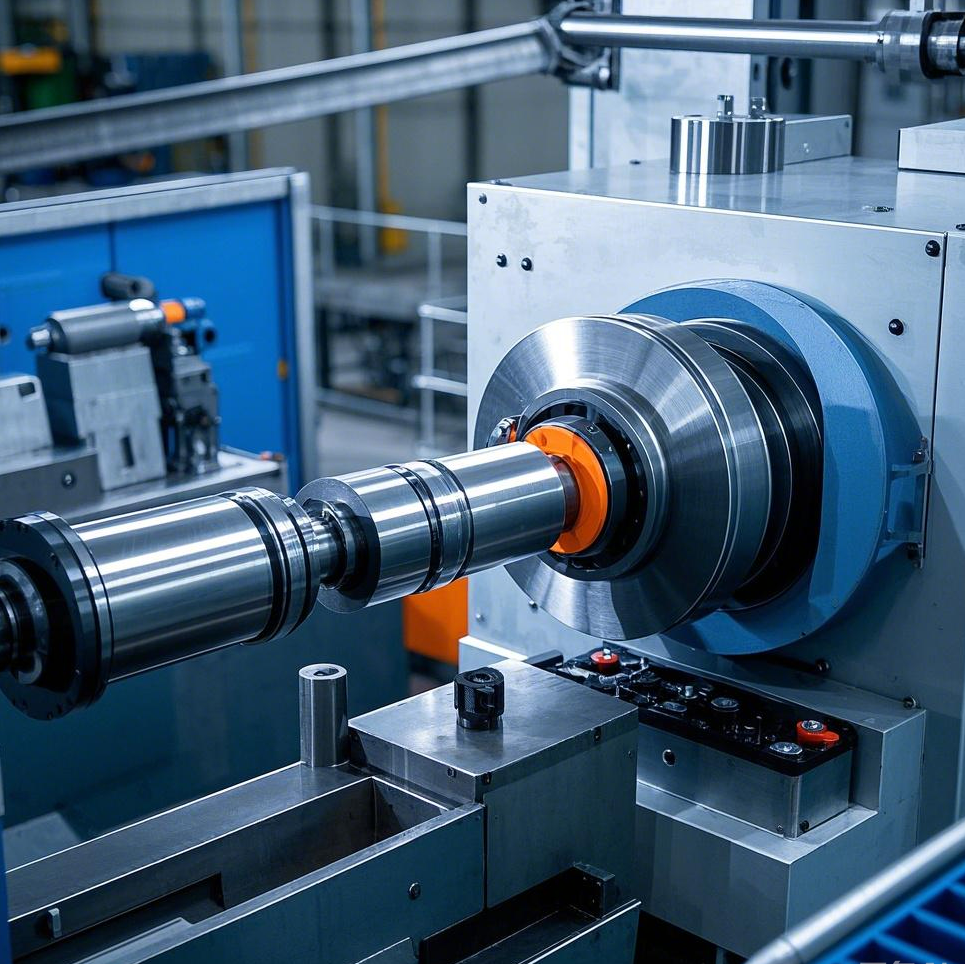

Spinning processing is a specialized sheet metal forming method used to create complex geometric features in sheet metal parts. During the spinning process, flat or hollow blanks are fixed onto the mold of a spinning machine. As the machine spindle rotates, the spinning wheel or drive rod applies pressure to the blank, causing localized plastic deformation. This technique can achieve various complex geometric shapes, including deep drawing, flanging, shrinking, and bulging, making it widely applicable in industries such as lighting, aerospace, and automotive manufacturing. In the customization of chandeliers, sheet metal shapes are typically designed in the early stages and then mass-produced using spinning equipment, ensuring that each product meets design requirements and maintains high consistency.

In the custom manufacturing process of chandeliers, sheet metal shaping is one of the key steps. After designers create unique shape designs based on customer requirements, spinning processing technology is used to transform these designs into physical products. First, flat or hollow blanks are fixed onto the mold of a spinning machine. Then, through the localized pressure applied by the spinning wheel or drive rod, the blanks gradually deform into the desired complex geometric shapes. Spinning processing not only efficiently completes processes such as deep drawing, flanging, shrinking, and bulging but also ensures high precision and consistency in the final products. This technology is particularly suitable for producing decorative components in chandeliers, such as lampshades, brackets, and connectors, adding unique aesthetic and functional value to the chandeliers.

High Precision: Spinning processing achieves high-precision forming of complex geometric shapes, meeting the design requirements of high-end lighting products.

High Efficiency: Automated spinning equipment enables rapid mass production, shortening delivery cycles.

Material Savings: As a non-cutting process, spinning processing minimizes material waste and reduces production costs.

Diverse Applications: Suitable for various metal materials, such as aluminum, copper, and stainless steel, catering to different product needs.

Strong Consistency: Spinning equipment ensures high consistency in every product, making it ideal for customized production.