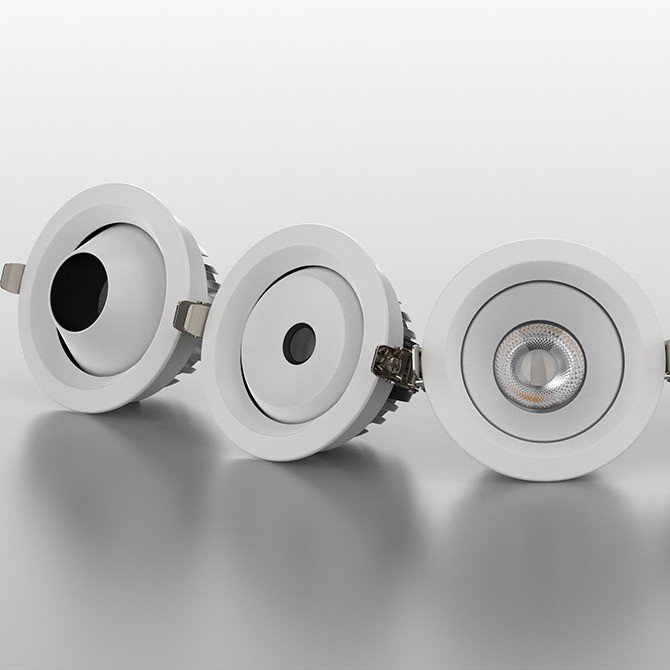

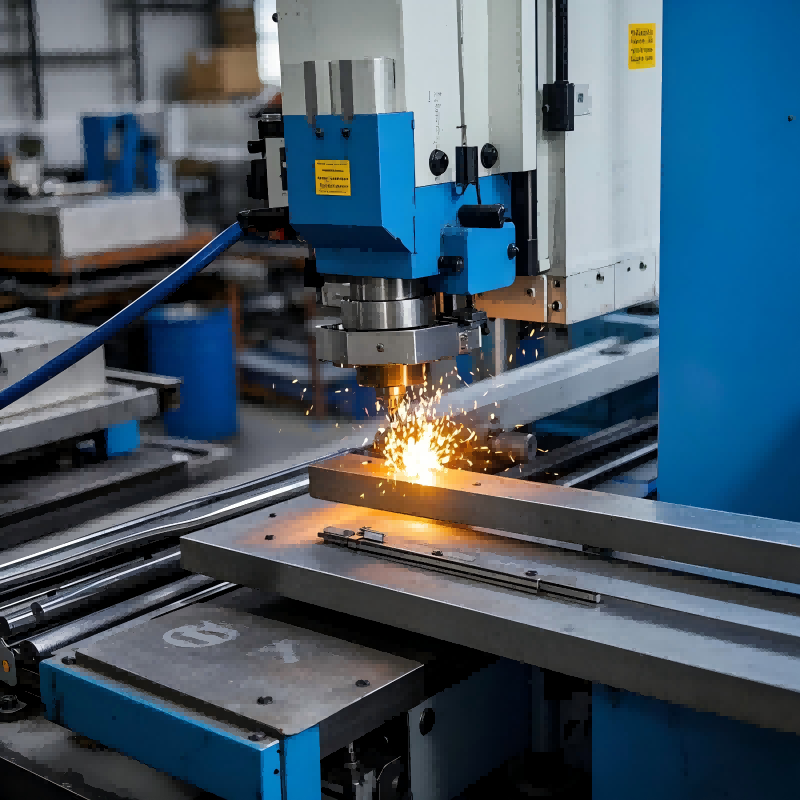

The sheet metal processing production at Dongguan Vssun Lighting Co., Ltd. includes multiple processes such as punching, stamping, bending, forming, welding, polishing, spraying, printing, and assembly. Each process utilizes advanced equipment and technology to ensure high precision and quality of the products. Among these, stamping processing technology is one of the core aspects of sheet metal processing. By combining fiber laser cutting and pressure equipment, metal materials are forcibly deformed or separated to produce precision parts that meet design requirements. These parts, commonly referred to as stamped parts in the lighting manufacturing industry, are widely used in the structural and aesthetic components of lighting fixtures. Our stamping processing not only offers high efficiency but also meets the demands for complex shapes and fine dimensions, providing customers with durable and visually appealing lighting products.

Stamping processing technology is a critical aspect of sheet metal processing, primarily used for fiber laser cutting and forming of metal materials. Through pressure equipment such as stamping presses, metal materials are forcibly deformed or separated to obtain product parts that meet practical requirements. In the lighting manufacturing industry, these parts are known as stamped parts and are widely used in structural supports, housings, and decorative components of lighting fixtures. Our stamping processing technology is characterized by high precision and efficiency, capable of handling parts with various complex shapes and sizes, ensuring that every product meets stringent quality standards.