Common Materials Used in Lamp Manufacturing and Their Characteristics

Aluminum Alloy

Aluminum alloy is one of the core materials in lamp manufacturing, widely favored for its lightweight properties, high strength, and excellent machinability. During production, aluminum ingots are melted at high temperatures and injected into die-casting molds to form key components such as lamp bodies, heat sinks, and bezels. Aluminum alloy is not only durable but also effective at heat dissipation, making it a popular choice for mid-to-high-end lighting fixtures.Zinc Alloy

Zinc alloy serves as a cost-effective alternative to aluminum alloy and is suitable for lamp structures with lower strength requirements. Although slightly heavier, it offers lower production costs and good workability, making it ideal for mid-range lamp accessories such as decorative parts and connectors.Steel Plate

Steel plate is a common material in lamp manufacturing due to its high strength and affordability. It is particularly useful for structural components that require load-bearing capacity. Through processes like stamping and bending, steel plates can be shaped into lamp frames, bases, and other supportive parts, offering both durability and flexibility in design.Plastic

Plastic is widely used in lamp production and comes in various types, such as polycarbonate (PC) and polymethyl methacrylate (PMMA). Typically processed in granular form, plastic is injection-molded to create lamp covers, housings, and decorative elements. Its advantages include lightweight properties, electrical insulation, and the ability to achieve diverse colors and light-diffusing effects, making it suitable for modern, minimalist lamp designs.Mirror Aluminum

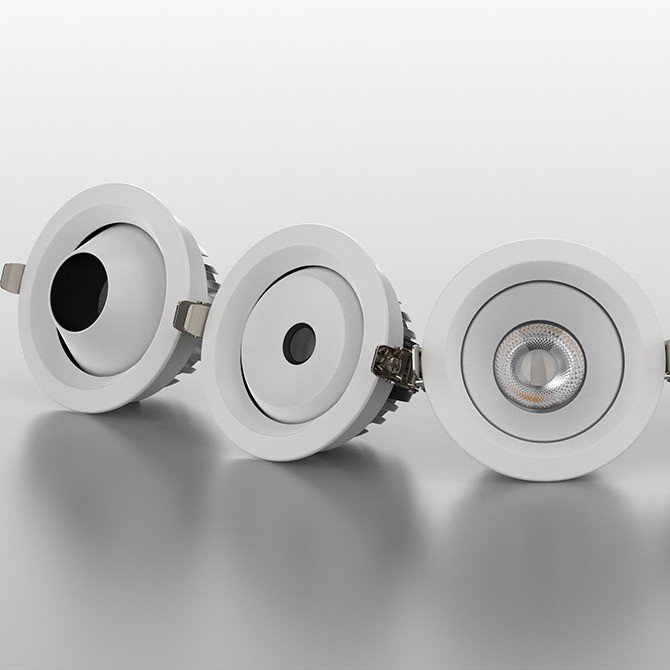

Mirror aluminum is a specialized material in the lighting industry, featuring a highly polished surface with superior reflectivity. It is commonly used to make reflectors for directional lighting fixtures, such as spotlights and downlights, due to its precise light control capabilities.Satin-Finished Aluminum

Unlike mirror aluminum, satin-finished aluminum undergoes a textured treatment to create a matte surface, producing soft, diffused light reflection. It is often used in fixtures requiring even illumination, such as panel lights and ceiling lamps, helping to reduce glare and enhance visual comfort.

Each material has unique properties, and manufacturers select the most appropriate one based on design needs, cost considerations, and functional requirements to achieve a balance between performance and aesthetics.